NERA

The most compact

and reliable solution

for solar pumping applications

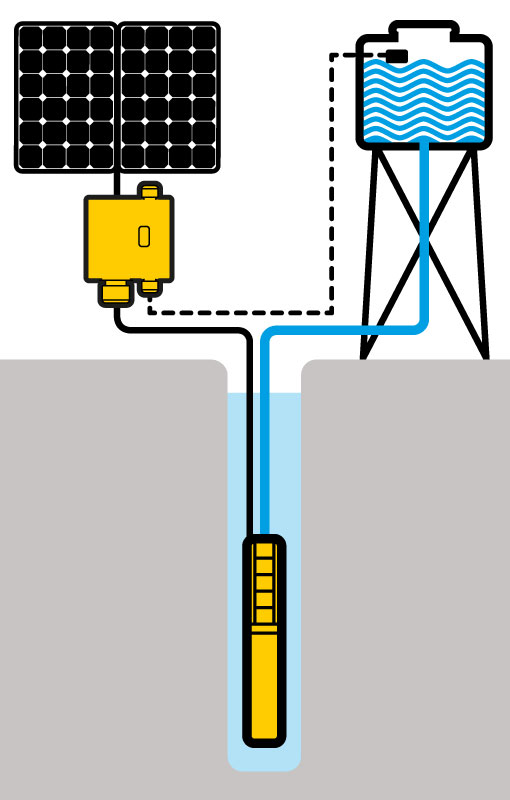

NERA solar pumps have been

developed to meet the needs of low-power

and low-cost pumping systems

without sacrificing quality, reliability and performance.