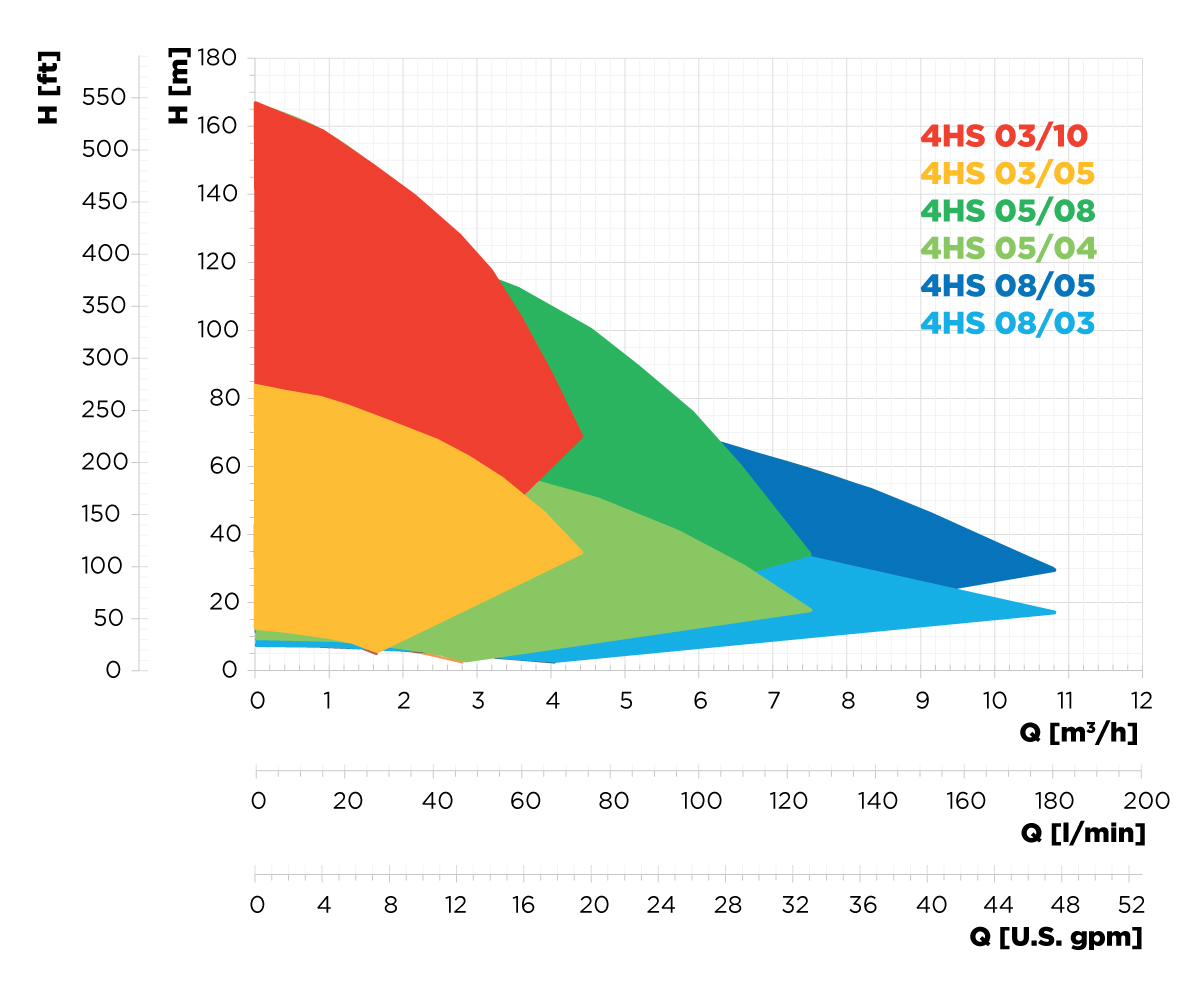

Pump selection

Variable speed allows 4HS to cover a wide range of water flow and heads with just a few models; selecting the proper pump model for an application will help maximise performance and overall efficiency. Use the diagram below to select the most suitable 4HS pump model for your application.

Energy saving

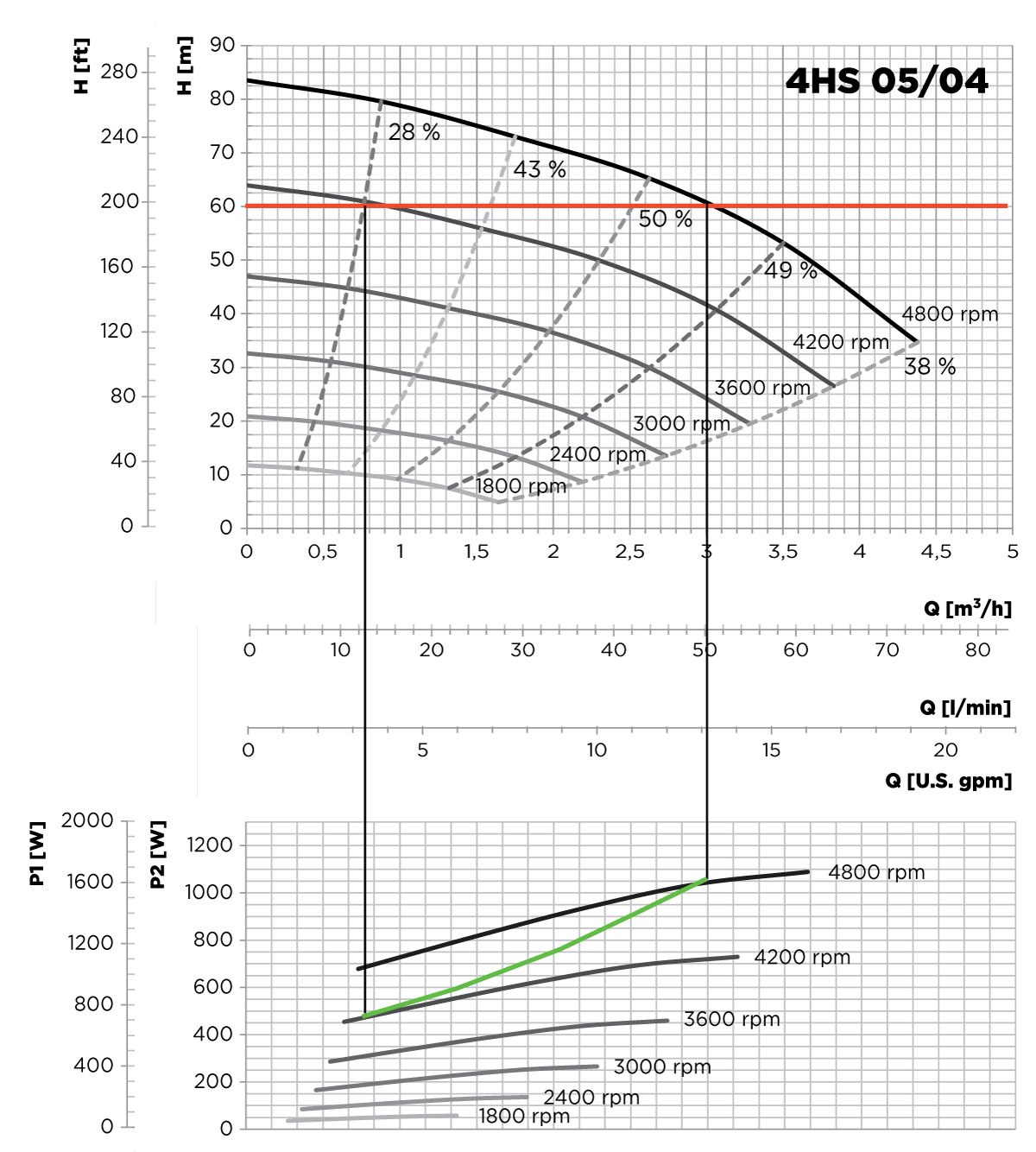

If the water demand decreses, 4HS will reduce the speed (proportional to the frequency) to maintain constant pressure. As you can see from the chart, a speed reduction corresponds a significant decrease of the power consumption. For example, maintaining constant the 6 bar (197 psi), if speed drops from 4800 rpm to 4200 rpm, input power decreases from 1600W to 700W.

Thousand pumps

4HS can be used at a fixed speed by setting the operational frequency. To each frequency curve corresponds a different hydraulic performance and power consumption. This means that each 4HS model covers the performance offered by several standard pumps at fixed speed.

Performance adapting

Among the parameters to be set in the CM control module, particularly useful is the possibility of limiting the maximum current absorbed by the pump. If this threshold is exceeded, for example in the even of a drop in input voltage, the control will reduce the 4HS pump speed to always ensure its operation.