Software implemented in each drive of VASCO – VAriable Speed COntroller range is the result of a long-time experience in solving customer requests and constantly following new drive applications.

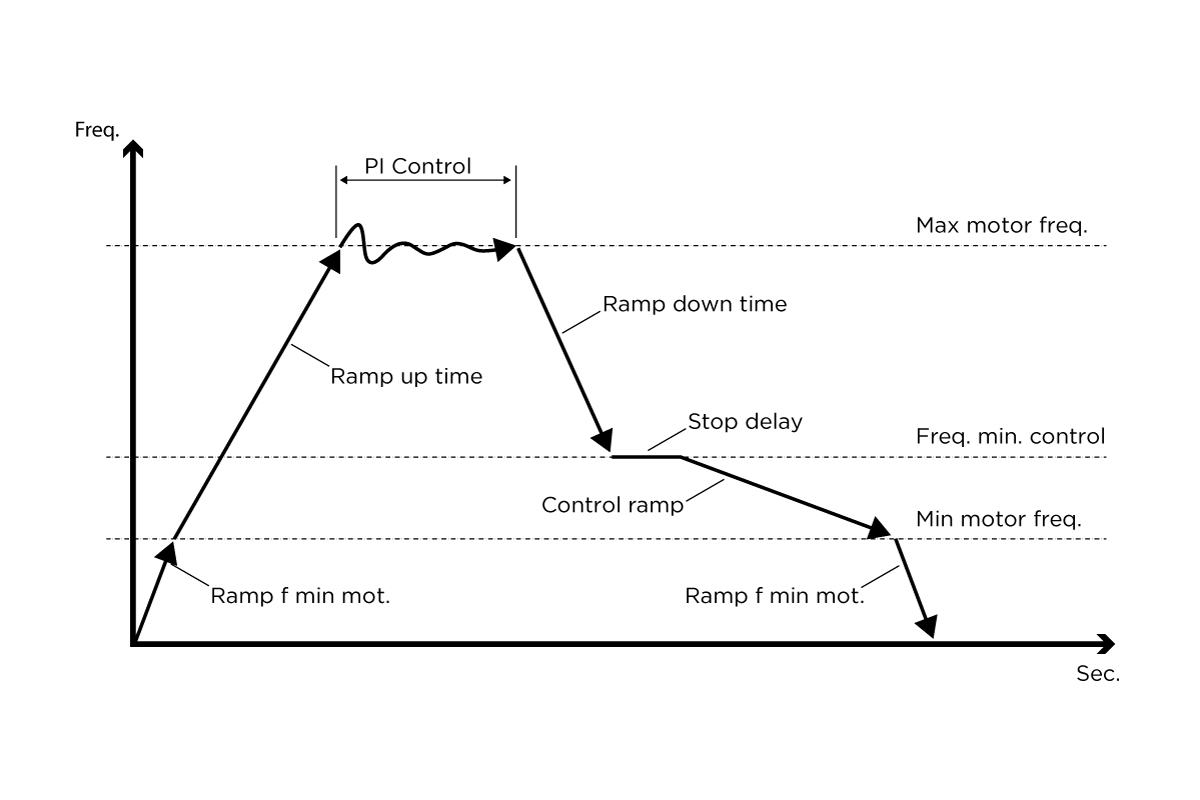

Minimum motor frequency.

This parameter prevents motor operation below a certain frequency, thus avoiding damage to the thrust bearing of the submersible motors.

Minimum motor frequency ramp.

Motor can accelerate from 0 to the minimum motor frequency following a very fast ramp and then go through a slower ramp.

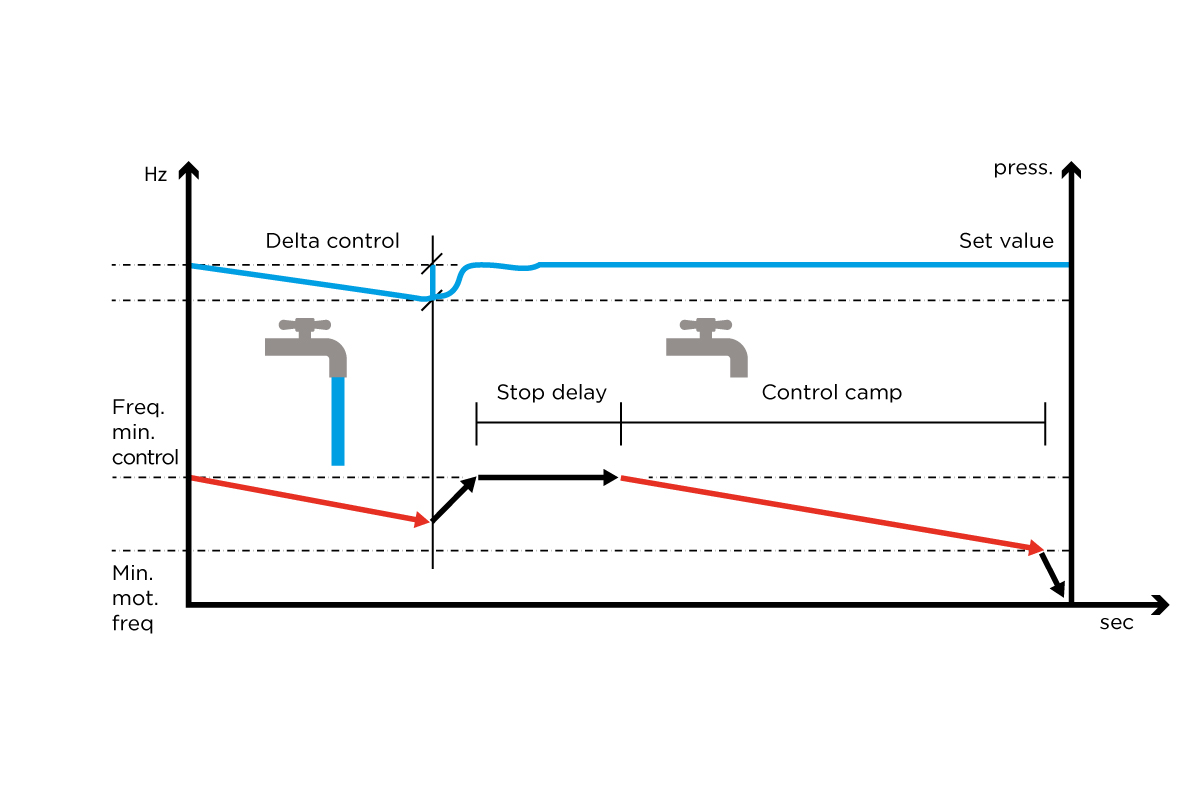

Intelligent stop of pump at no flow condition.

Below minimum control frequency, the device gradually reduces the pump speed while monitoring the pressure transducer signal. If this value is maintained close to the set pressure, the device will reduce furthermore the output frequency till stopping definitely the pump.

Maximum and minimum alarm pressure.

When the pressure rises above a certain settable pressure value, the device will stop the pump to prevent damage to the hydraulic components in the system. Similarly, if the pressure drops below a certain pressure an alarm is triggered and the pump is stopped.

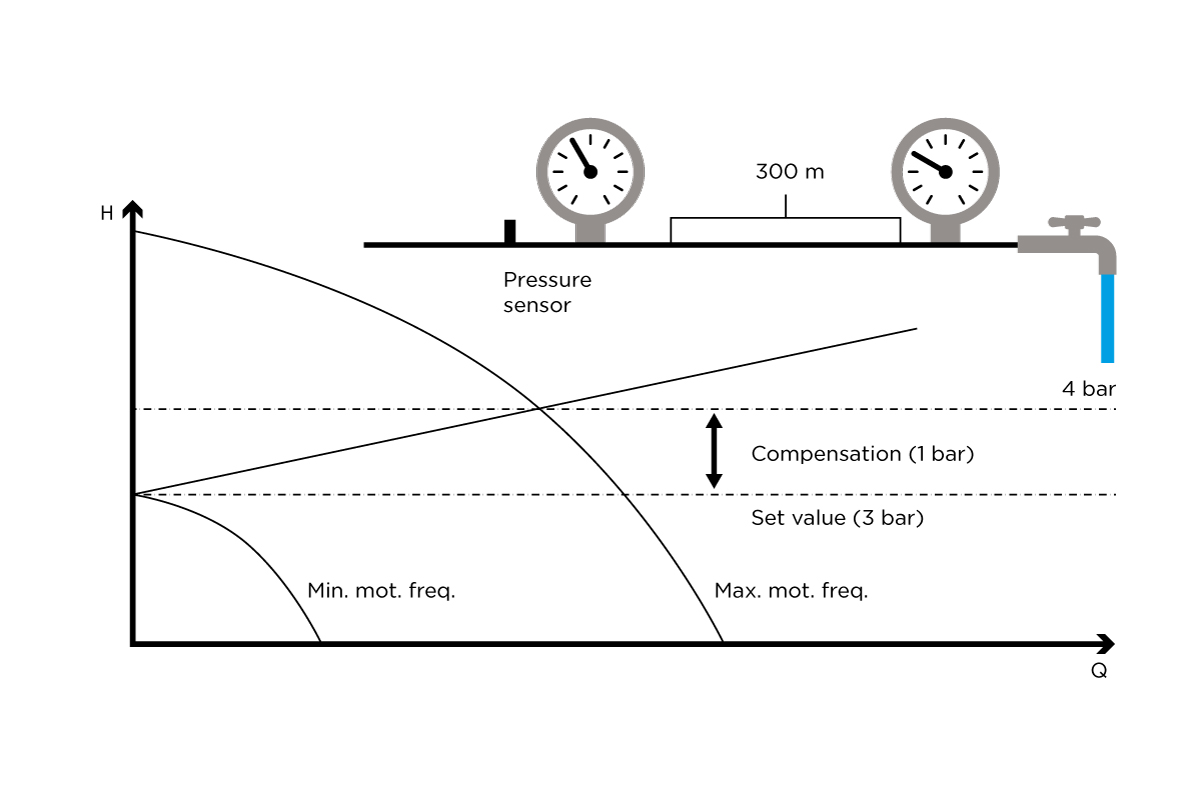

Loss compensation proportional to the water flow.

If the pressure sensor is placed near the pump, with the increase in flow the pressure value at the furthest outlet is lower than the set pressure. It is possible to vary the set pressure in proportion to the frequency to compensate pressure loss in the pipes.

Dry running alarm via cosphi value.

If the pump runs dry, its cosphi value drops below a settable cosphi value, and the device stops the pump after 3 seconds. Device will try to make 5 attempts every 10, 20, 40, 80 and 160 minutes, after which it will trigger an alarm and stop the pump if the condition persists.

V/f programmable curve.

VASCO – VAriable Speed COntroller offers two different methods of torque control (voltage) versus pump speed (frequency):

- constant torque (linear V/f)

- quadratic variable torque (squared V/f)

For centrifugal pumps, energy savings can be obtained by selecting squared V/f control.

Settable carrier frequency between 2.5, 4, 6, 8, 10 kHz

If the device controls a submersible pump with long cables, it is possible to decrease the carrier frequency value to ensure longer motor life.